Despite little being known about the principles of mechanical stress and their relationship to accuracy, it is generally accepted that rifle components will be affected by certain stresses. Stock movement due to changes in temperature and humidity can induce stress and the result will normally be seen as a change in either the groups point of impact or size. For these reasons, the largest percentage of our rifles are built on synthetic stocks.

McMillan

The majority of our rifles are built on McMillan synthetic stocks. Due to their quality of construction these stocks are supplied with an unconditional lifetime guarantee against warping, splitting or cracking under normal conditions of use. McMillan stocks are manufactured from layers of fibreglass cloth, impregnated with epoxy resin, moulded together at high pressure. All inletting work is completed on CNC milling machines. With a choice of over 60 different shapes including many copies of factory stocks there is generally a model to suit each purpose. Available finishes include many moulded-in solid or marbled colours, camouflage patterns and a selection of four polyurethane painted colours. A full catalogue is available on request or visit their website at www.mcmfamily.com.

We will not, under any circumstances, build any custom rifles on injection moulded plastic stocks.

Bedding

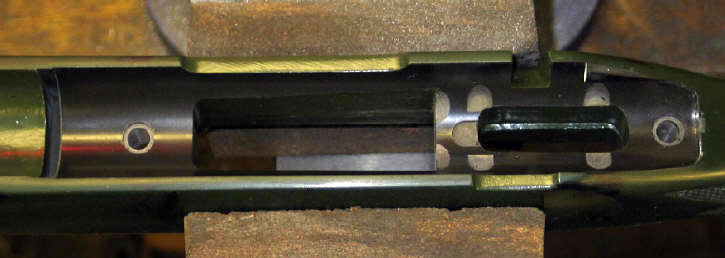

The purpose of bedding is to mate action and stock together. This process ensures that there is no movement under recoil, however, care must be taken not to create tension in the metalwork which causes inconsistent vibrations. We have tight maximum tolerances on bedding stress which are easily measured with a 0.001″ dial indicator. All barrels are left fully floating.

Actions are bedded using a pillar bedding system with Marine Tex or Bisonite. The pillars are either of machined aluminium or epoxy depending on the depth of the stock at each of the action bolts. Grooves are machined on the circumference to give a good epoxy bond between the stock and the pillars. No direct contact is made between a metal pillar and the action as it is extremely difficult, if not impossible, to get a perfect fit between solid pillars and an action while maintaining an evenly distributed contact on the remainder of the bedding surface.